The new generation ( Tier 3/Stage III-emissions compliant ) engines now on the market from leading construction equipment suppliers provide very low emissions levels to meet the latest environmental regulations. But how well do they deliver in terms of fuel economy and long-term durability? Angus Fotheringham, Komatsu Australia’s Business manager, general construction, provides some answers.

The current generation of Tier 3-compliant engines have been designed to meet very stringent emissions regulations put in place by environmental agencies in Europe, the US and Japan – and as such, represent the pinnacle of construction equipment engine technology.

Having said that, we can expect to see even more work on construction engines over the next few years, to achieve Tier 4 regulations (coming into force in the US between 2011 and 2015). Already, the on-highway transport industry is rolling out Tier 4-compliant engines.

To meet the current Tier 3 requirements, the current generation of engines use various methods to minimise the levels of nitrous oxide (NOx), particulate matter (PM) and other emissions that pollute the air.

Common to all engine manufacturers’ solutions are very precise electronic engine management systems that can very accurately measure and meter the levels of fuel and air being delivered to the combustion system.

As with all modern diesels, critical factors include clean fuel and correct filtration management, the correct engine lubricants, and proper engine maintenance management practices.

However, in achieving the lower emissions required under Tier 3, different manufacturers have adopted different approaches.

In Komatsu’s smaller ecot3 construction equipment engines, Tier 3 compliance is being achieved primarily through sophisticated electronic engine management.

In its larger construction equipment engines, Komatsu, as with most other major engine manufacturers, has opted for what is known as cooled exhaust gas recirculation (EGR) as part of its ecot3 solution to comply with lower emissions standards.

As its name implies, EGR involves recirculating a portion of cooled exhaust gases so that the NOx and PM levels are further reduced when the exhaust gases are released to the atmosphere. This process also helps to reduce any unburnt particulates during the combustion process.

EGR technology is not new; it has been around for at least 30 years, and is regarded as reliable and well proven – although today it is applied to modern engines in a far more technically advanced manner. In addition, EGR does not require the fitting of a particulate filter, which requires periodic replacement.

But in addition to EGR, Komatsu’s new generation ecot3 engines combine a number of other advanced-technology solutions. These include:

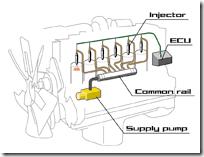

- A high-pressure common-rail multi-stage fuel injection system

- A patented piston/cylinder design to deliver more complete burning of fuel

- An advanced engine management system that controls the burning of emission-causing particulates inside the cylinder.

These processes, combined with a liquid-cooled heat exchanger, significantly cool the recirculating exhaust gases before they re-enter the cylinder, resulting in a system that runs more efficient than other EGR-based engines.

In addition, Komatsu’s ecot3 unique cylinder design results in greatly improved combustion, for a far more efficient fuel burn.

The end result of this technology, in addition to significantly lower emissions, is reduced fuel consumption – a major cost-saving benefit in today’s environment of high fuel costs.

So what are the key factors in engine life? There are five critical factors that all diesels – no matter what their age or technology – require for efficient, reliable and long-term operation. These are:

- The right operating temperature (in other words, correct cooling)

- Clean recommended engine oil

- Clean air

- Clean fuel that meets the required standards

- Regular maintenance (including oil analysis).

But there is one more factor that is often overlooked: Fuel burn.

An engine that burns more fuel – in other words, that is less fuel efficient – will have a shorter life than an engine burning less fuel.

Fuel burn, the amount of diesel that goes through an engine during its life, has a direct correlation to engine longevity. The more fuel an engine burns, the harder the components are working, and the sooner it will wear out.

Conversely, a more fuel-efficient engine – one that burns less specific fuel – won’t be working so hard and will have a longer life (all those other factors mentioned above being equal).

That’s why good fuel efficiency at optimum performance should be a key element that customers look at when choosing a machine.

Not only will the machine be kinder on your hip pocket every time you go to fill it up, but – provided you look after it and comply with the manufacturer’s maintenance requirements – you will get a longer life from it. That’s an important consideration when you think that approximately 30% of a machine’s repair costs over its life are in the engine.

In addition, the more fuel-efficient a machine is, the fewer emissions it will be producing per tonne of production, simply because it’s burning less fuel.

And that’s why Komatsu has paid considerable attention to developing Tier 3 engines that are more fuel-efficient than their Tier 2 predecessors.

As an example, Komatsu’s recently released WA600-6 wheel loader, with our new ecot3 Tier 3 engine is already proving more fuel-efficient in heavy duty quarrying face loading and load-and-carry operations in Australia than its Tier 2 predecessor.

In contrast, there are some Tier 3 engines around from other manufacturers which burn more fuel than their Tier 2 predecessors.

All this places Komatsu in a leading position in the move to Tier 4 requirements in the next few years, with Japan looking to demand the most stringent emissions requirements of any country.

And unlike other manufacturers’ solutions, Komatsu’s ecot3 technology is already “Tier 4 ready”, and therefore well positioned to meet these requirements, at the same time delivering unmatched fuel efficiency with longer engine life and better reliability.

Sumber : Komatsu Australia

Klik disini untuk melanjutkan »»

![clip_image001[4] clip_image001[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgiN3RVbU88R9O2CaFo79_UM86KVsSl23xASQjkqvw3fjjEIWprK9wpYJMnB-RzsOH_SalCPlYlJrJouxdqV8O6uHMJw3E0zJxNnRj8NUvKK05kOPluO2YAEZNGOE9CL-DiZE2fcXDZ7zw/?imgmax=800)

![clip_image001[6] clip_image001[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjHnXK5V5K1tQ8-P05gf41cuwlQWPX6elowXsKgMFJiYD-VKVg7YdKS7LcrW56AgUU6Np6_n1XIc8cROLSLbExyRFXo4EysfmBn5Z7VpddMuW-_ZS7tdk6H63CPD8ADB8hKPcyjon7h43c/?imgmax=800)